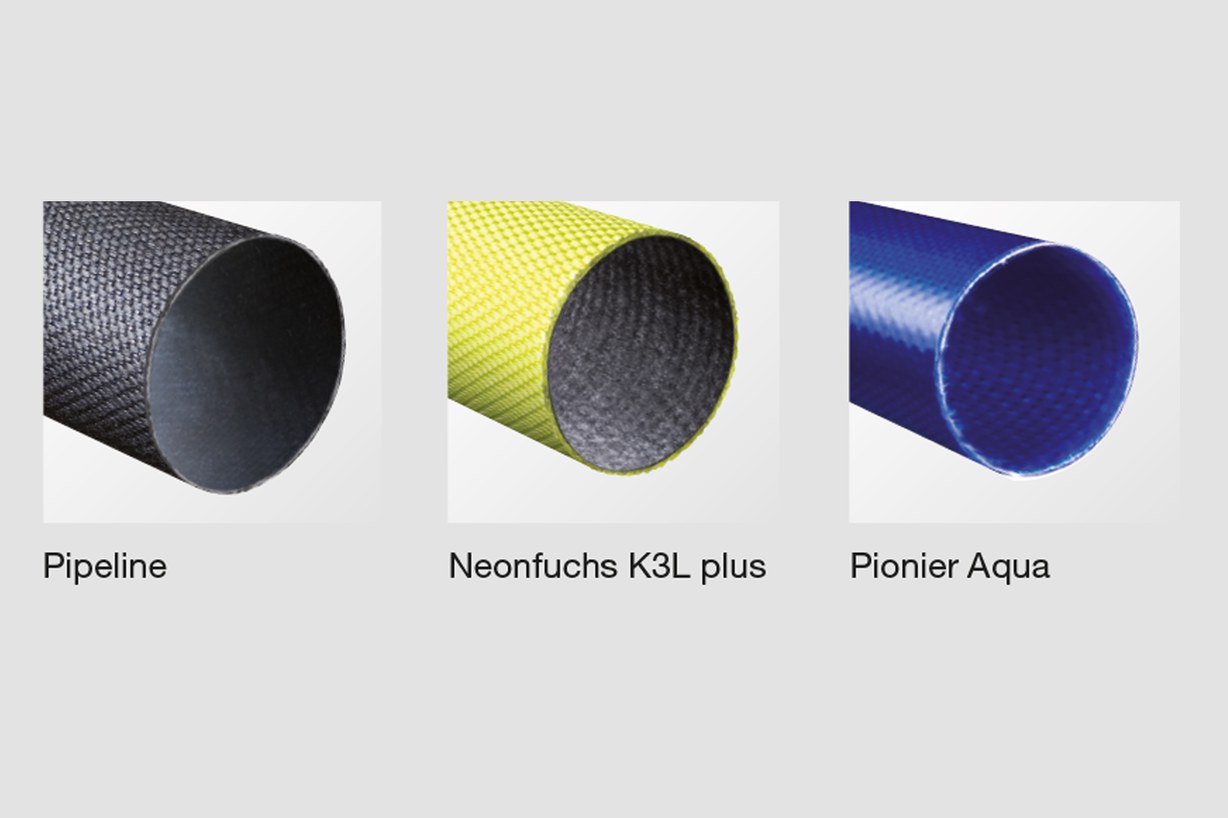

Applications: Fire, industrial, military and maritime

You can speak of tradition, because fire hoses are manufactured at ZIEGLER for more than 130 years. Since 1891, the merchant Albert Ziegler in the "Klingelmühle" specialized the company in the manufacture of fire hoses. At that time, and until 1950, the hoses were produced on flat looms. Why hemp as material preferred was in use, which welled up in the wet state and ensured tightness of the hose.

Applications: Fire, industrial, military, factory fire brigades and chemical industries

You can speak of tradition, because fire hoses are manufactured at Ziegler for more than 125 years. Since 1891, the merchant Albert Ziegler in the "Klingelmühle" specialized the company in the manufacture of fire hoses. At that time, and until 1950, the hoses were produced on flat looms . Why hemp as material preferred was in use, which welled up in the wet state and ensured tightness of the hose.

Applications: Reffinery, industrial, military, factory fire brigade and chemical industries

You can speak of tradition, because fire hoses are manufactured at Ziegler for more than 125 years. Since 1891, the merchant Albert Ziegler in the "Klingelmühle" specialized the company in the manufacture of fire hoses. At that time, and until 1950, the hoses were produced on flat looms . Why hemp as material preferred was in use, which welled up in the wet state and ensured tightness of the hose.

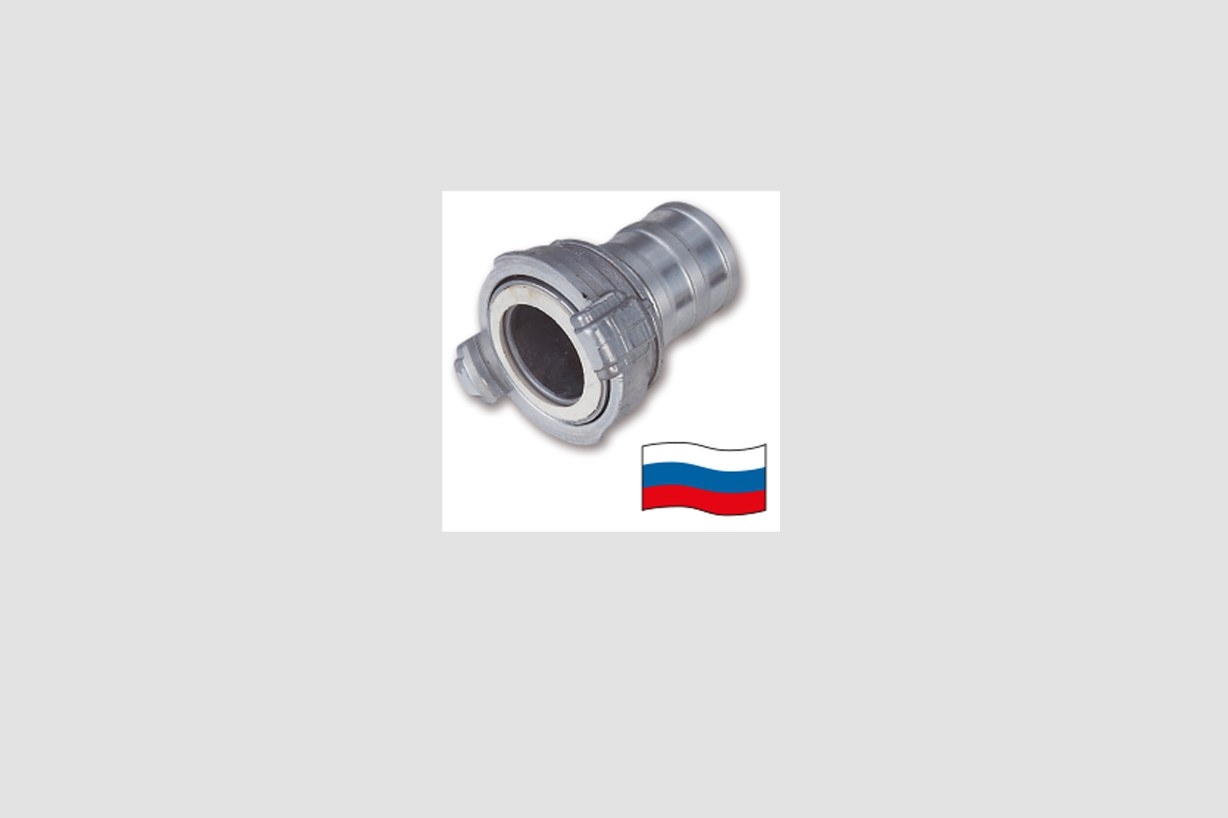

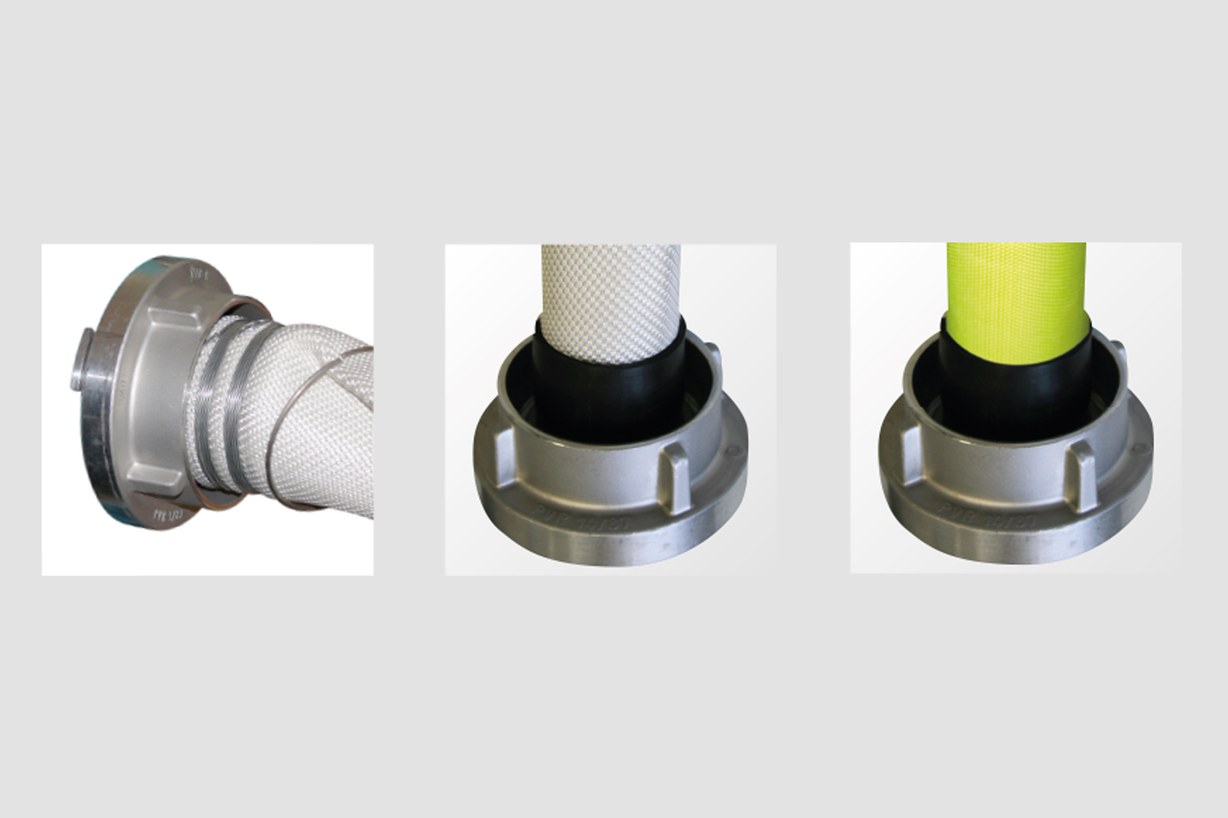

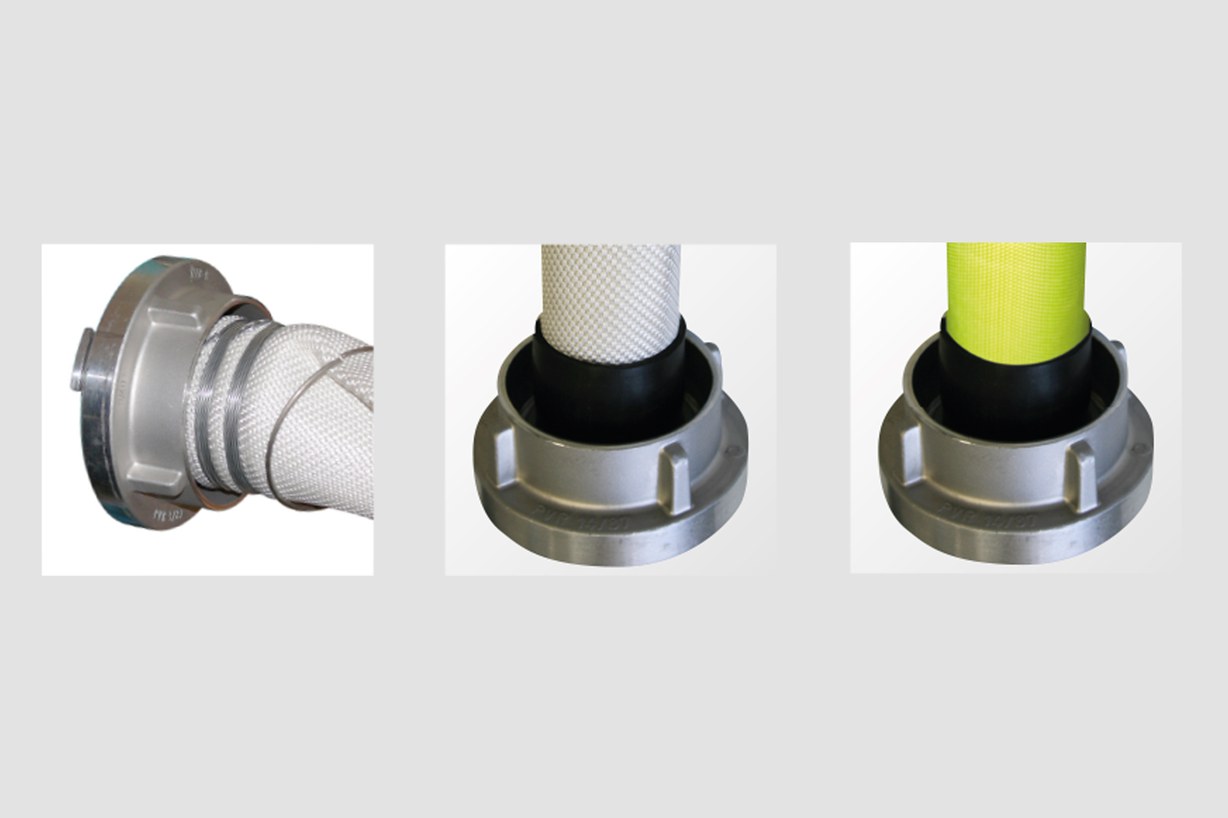

Coupling systems for fire department hoses

The Ziegler hoses can be individually integrated with national or international couplings. Pictured above clutch systems are just a selection of the most common types.

The Ziegler hoses can be individually integrated with national or international couplings. There are possibilities for protection of the bandage and against abrasion at the hose connection piece.

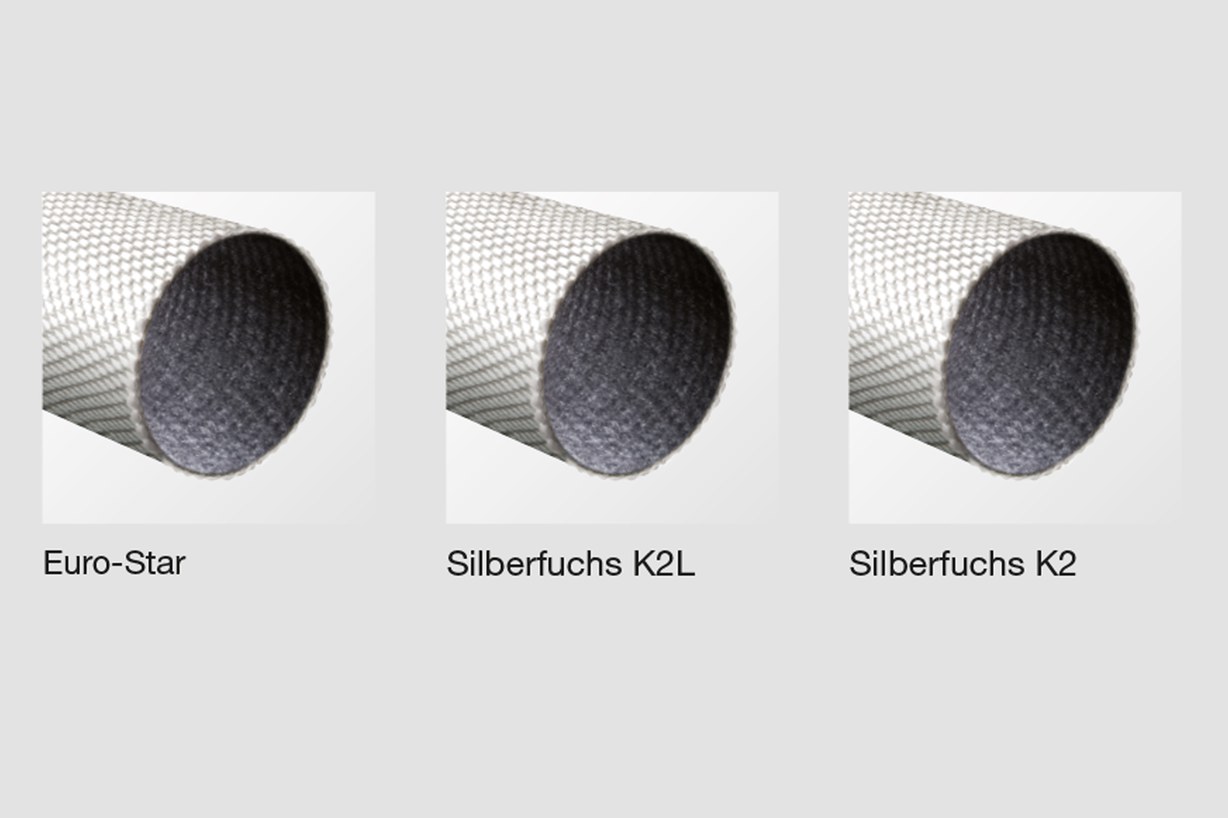

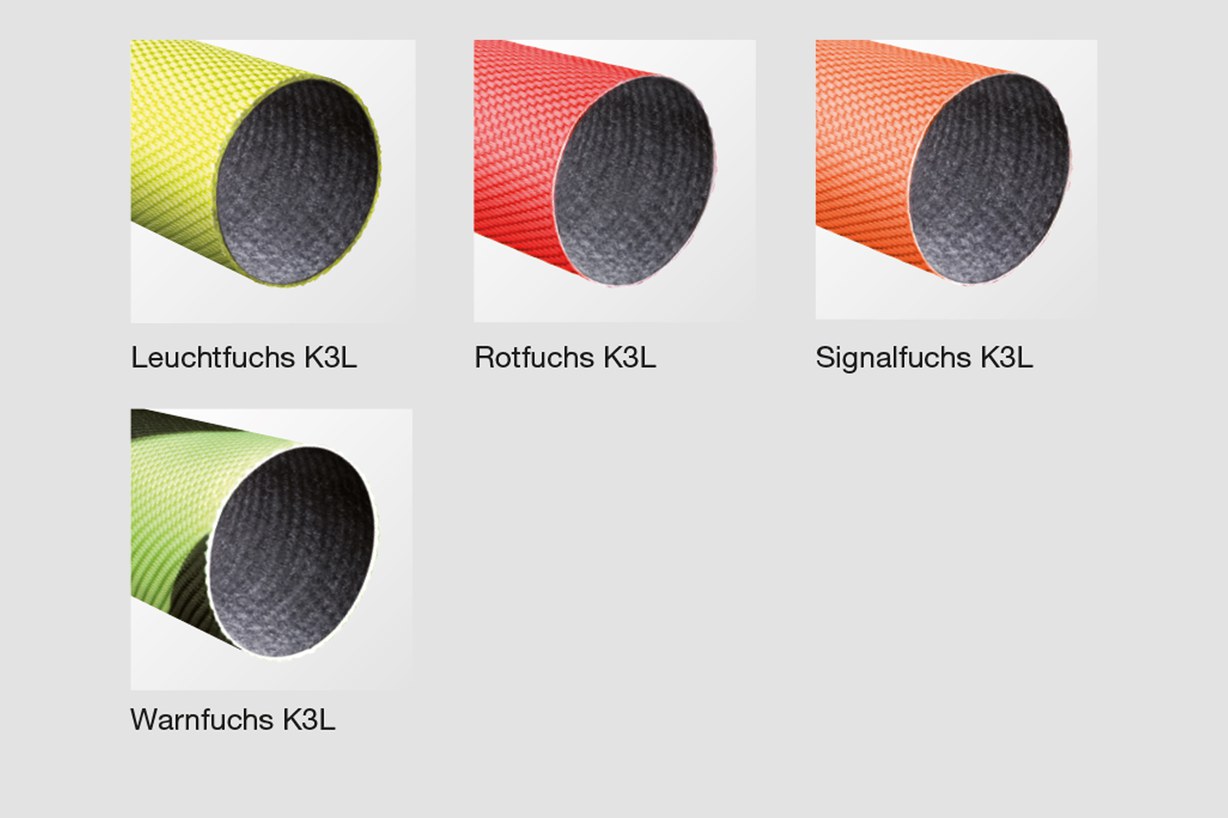

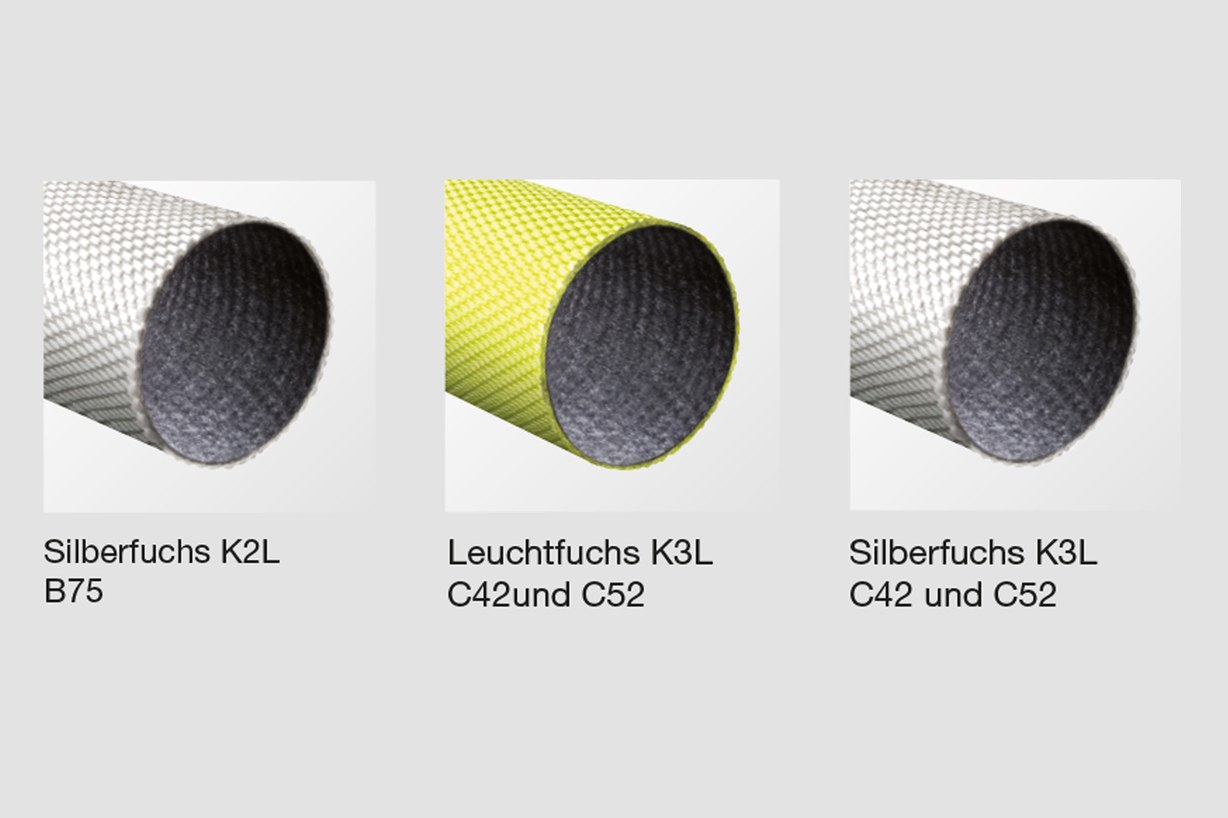

The new performance levels serve the purpose of an elevated abrasion resistance to external influences first and foremost.

This was increased at C hoses compared with the old standard as follows: in output level L1 to 2.5 times, at output level L2 to the 5 times and at output level L3 to the 7.5 times.

B hoses there are no changes in output level L2 a boost of 50% and for output level L3 a boost in output level L1 75%.

In addition, a so-called shock protection is required for levels L2 and L3. For the output level L1, this protection is optional. Also all new hoses have to have in the future a stainless steel cover.

Thus, it creates a base that provides users with a quality appropriate for their needs.

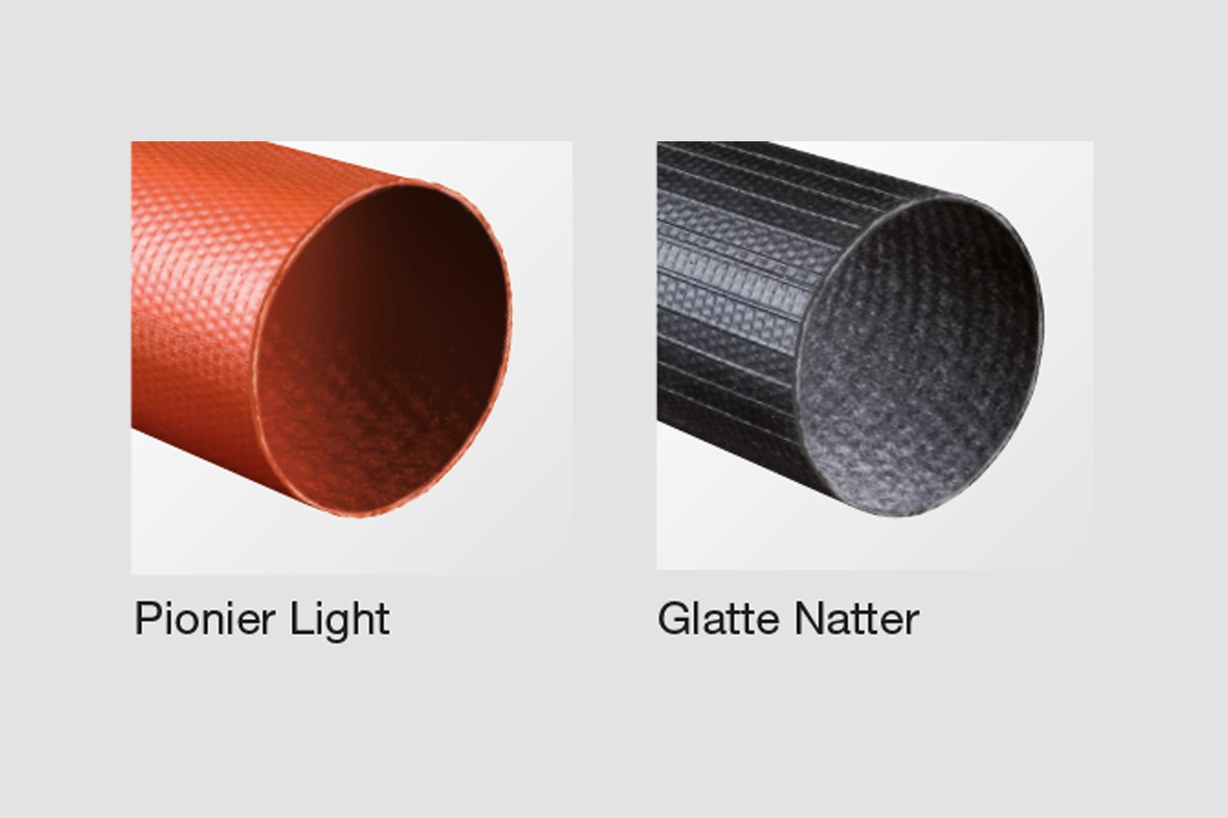

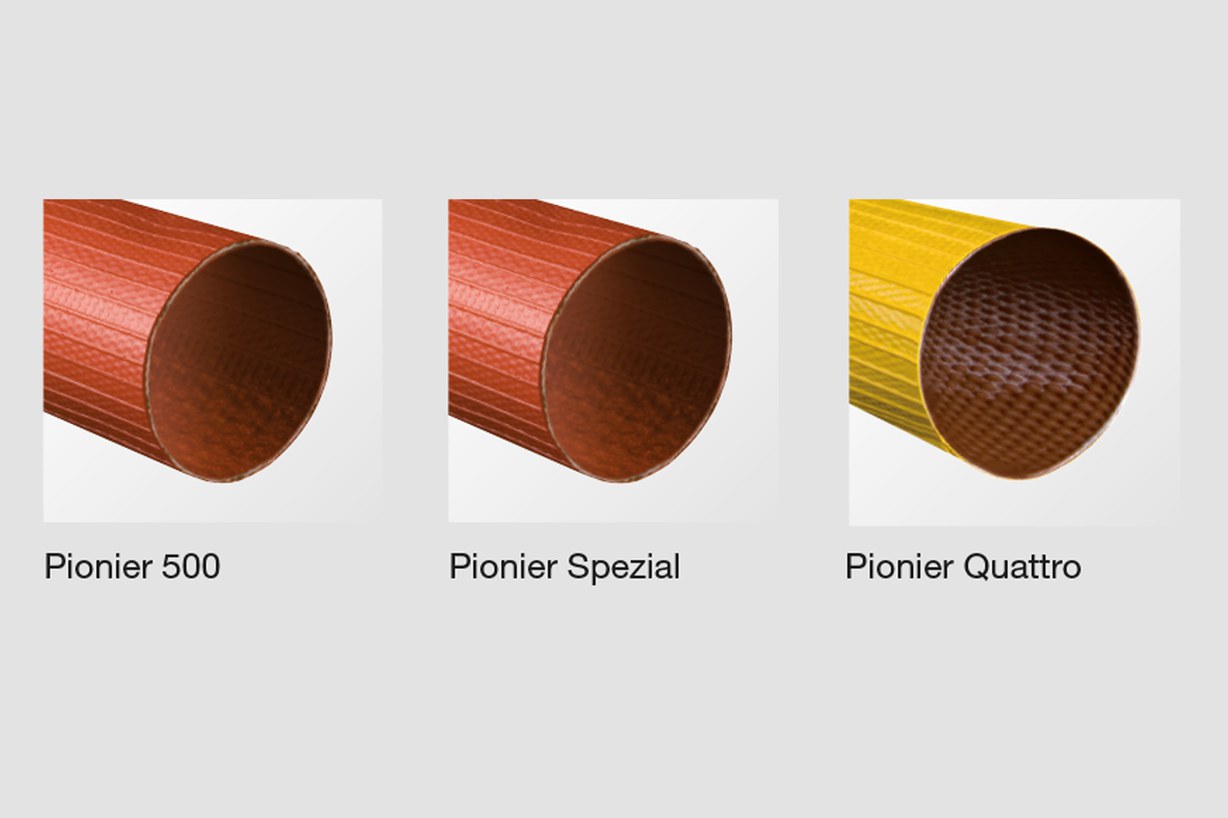

The circular weaving process have prevailed from the 1950s and also even polyester has been introduced at that time as fibre material. Because polyester fibers do not swell, an elastomer as inner lining in the hose must be submitted in a high-tech process to ensure tightness.

The hose manufacturing is still an important branch of the company. Today, more than 20 round looms produce daily around 6,000 metres of fire hoses in a wide range of variants. With the 60 million meters produced hose you could smooth one and a half wrap around the earth.

"We provide security" - the brand promise clearly shows what the brand ZIEGLER stands for - in every sense of the word. Especially the direct contact is important to us. ZIEGELER customers trust anywhere in the world. For 125 years. Today. And in the future.

Through our representatives, we are sure that you have a direct and competent contact partner every time.

For further questions or requests, please use the following contact form. Your address and your fire department/agency/company help us to respond to your request quickly. Of course, we will treat your data confidentially.

link to contact form Ziegler International